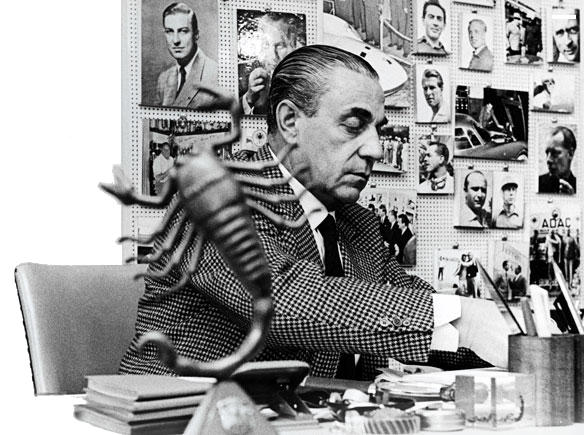

Join us for the next chapter of our story.

This year, following a highly successful re-launch, we’re welcoming you to step inside the world of Abarth.

Each month we’ll give you a new behind-the-scenes look into the philosophy, the process, the people and the parts, that go into every car. Find our why we’re so proud of our heritage and how we work on a daily basis